IPL Industrial Camera

for Automated Optical Inspection

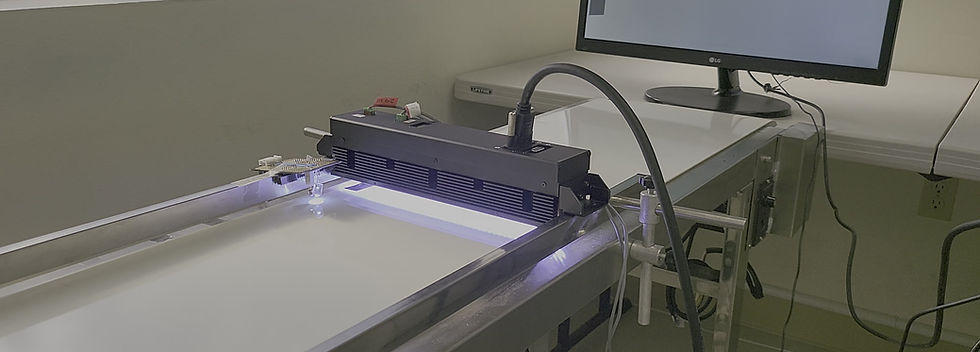

IPL - Industrial Proximity Linear

Patented, Low-Profile Machine Vision Camera With 1:1 Crystal-Clear Color Image Acquisition

Capture unparalleled 1:1 high resolution color images for AOI with the Industrial Proximity Linear's (IPL) close proximity line scanning methodology.

Surpass conventional line scan camera limitations.

The IPL's wide-scan design and less moving parts saves you from needing additional line scan cameras, maintenance costs, and maintenance hassle.

A New Generation of Industrial Cameras

IPL Advantages:

-

High Resolution Imaging: Close proximity line scan methodology with SELFOC Lens Array (SLA) captures unparalleled 1:1 crystal-clear high resolution images at up to 20KHz scanning speed*.

-

Very Low Profile: 34.2 cm x 6.35 cm x 6.69 cm. A better fit for your logistical needs.

-

Less Maintenance Hassle: Durably encased in anodized aluminum housing, less moving parts = Save on maintenance cost. Easily replaceable means less maintenance hassle.

IPL Industrial Camera Product Lineup:

Model # | Scan Width | Illumination | Spectrum | Interface |

|---|---|---|---|---|

IPL S206-0259-CICL | 259 mm | Built-in 30° Bright Field (Controllable) | Red, Green, Blue, Near-Infrared (Controllable) | Camera Link |

IPL S206-0259-CICL | 259 mm | 內建30°明場(可控制) | 紅色、綠色、藍色、近紅外線(可控制) | 相機連結 |

IPL S206-0518-CICL | 518 mm | Built-in 30° Bright Field (Controllable) | Red, Green, Blue, Near-Infrared (Controllable) | Camera Link |

IPL S206-0518-CICL | 518 mm | 內建30°明場(可控制) | 紅色、綠色、藍色、近紅外線(可控制) | 相機連結 |

IPL S206-XXXX-XXXX | CUSTOM | CUSTOM | CUSTOM | Camera Link |

IPL S206-XXXX-XXXX | 自訂規格 | 自訂規格 | 自訂規格 | 相機連結 |

IPL Industrial Camera Applications

Printed Circuit Board Inspection

Wafer Inspection

Electric Vehicle Anode Copper Battery Foil Inspection

Machine Vision for surface inspection

-

Wafer inspection

-

Printed Circuit Board inspection camera (for PCB inspection systems)

-

LCD panel inspection

-

Surface Mount Technology inspection camera (SMT inspection)

-

Electric vehicle battery copper foil inspection camera

-

Large panel glass inspection

-

OLED panel inspection

-

Printing press inspection

-

Textile inspection

-

AOI systems utilizing machine vision for inspecting medium-to-large flat-surfaced objects.

IPL Specifications

-

Image Resolution: 600 dpi

-

Imaging Colors: Red, Green, Blue, White

-

Sensors: 18 x C206 linescan image sensor

-

Line Rate: 100 - 20kHz line/sec Monochrome Max. line rate scanning frequency

-

Scan Speed: Maximum of 45.68 meters per minute in Monochrome mode

-

Operating Temperature: 0 - 50°C

-

Pixel Clock Rate: 8 MHz fixed

-

Exposure Control: 50 µs - 10 ms

-

Bit Depth Resolution: 8-bit / 12-bit

-

Scanning Width: 0.259 meter (Customizable based on needs)

-

Working Distance: 15.27 mm

-

Depth of Focus: +/- 0.6 mm

-

Dual Power Supply: 5V for Main board, 24V for LED array board

-

Image Capture Trigger: Line rate & exposure time by internal or external trigger

-

Camera Link: 26-pin MDR - SDR

-

LED light exposure control: Built-in four 30° Bright Field Illumination light sources with full software control

-

All-In-One Design: Sensor Array, Image Processing, Light Source, and Lens

-

Very Low Profile: 342 mm x 63.5 mm x 66.85 mm

259 mm

Scan Width

(Customizable)

342 mm

Full Length

(Customizable)

A Unique Line Scanner With 1:1 Crystal Clear Image Acquisition

Many conventional line scan and area scan cameras have issues with lens distortions. CCD line scan cameras use conventional lenses that result in barrel distortion, pincushion distortion, vignetting, and chromatic aberration.

CMOS Sensor Inc has designed the Industrial Proximity Linear (IPL) industrial camera to solve these typical line scan camera issues and deliver to you 1:1 accurate image acquisition.

The Industry Proximity Linear industrial camera utilizes a close proximity scanning methodology to capture uninterrupted 1:1 accurate high-resolution images.

Overlapping Placement of Sensor Chips Allow for Comprehensive Scanning Without Optical Gaps

Similar competing scanners stack sensors side-by-side, a design technique known as sensor butting, which results in very fine optical gaps between each sensor. They then resort to software to correct for this constraint.

The IPL eliminates these optical gaps at a design level: The IPL's 18 sensor chips are slightly overlapped to achieve a uniform, comprehensive scan. This design methodology ensures that your machine vision will be free from any optical gaps that could result in micro defects slipping through.

Typical competitors' sensor-butting design causes micro-optical gaps.

IPL has full optical coverage by design.

High Scanning Line Rates Captures Fast Moving Objects in Assembly Line

Conventional area scan camera setups that utilize a singular area scan camera take longer. A single line of objects waits for inspection as a singular area camera or object scanned must reposition itself over and over to take multiple images for coverage.

These area scan cameras have far more moving parts, prone to assembly and maintenance headaches. To remedy this, CMOS Sensor Inc has developed a 600 DPI wide line scan camera capable of capturing 1:1 accurate two-dimensional images at high line rates up to 20 KHz*.

The IPL enables high resolution inspection images to be captured and transmitted while the conveyor is in motion, allowing for more efficient quality control.

*20KHz line rate is the max scan speed available with the IPL's Monochrome mode and color Fast Scan mode.

Save the Hassle of Integrating Many Cameras: One Elegant Line Scan Camera for Your Large Surface Machine Vision System

AOI systems have traditionally relied upon multiple line scan cameras or multiple area scan cameras for larger flat surface inspection.

With this conventional setup, each camera needs to be correctly aligned so that complete image coverage of the inspected object is achieved. Usually, each inspection camera is linked to its own individual computer.

Conventional setups are complicated.

But with more cameras and more equipment comes more cost, more logistical hassle, and more maintenance hassle if even one camera stops working. Having multiple line scan cameras may increase the risk of defects and delays in production.

Utilize the advantages of IPL's scanning methodology to save the hassle and cost of part-by-part maintenance conventional multi-line scan camera setups would bring.

CMOS Sensor's IPL is designed to simplify your AOI system's large surface line scan processes.

The IPL is simple.

Bringing Color Imaging to Your AOI System with Software-Controllable Color Line Scan Cameras

The IPL now comes with full support for Red, Green, Blue, and White lighting and features high resolution color image capturing.

The built-in 4-LED brightfield illumination is completely configurable by software.

Employ CMOS Sensors for Quick Image Data Transfer

Compared to conventional CCD line scan cameras, CMOS line scan cameras transmit data faster.

Each IPL industrial camera utilizes 18 of CMOS Sensor Inc's breakthrough C206 line scan sensor.

Anodized Aluminum Housing: Durably encased, less moving parts = Save on maintenance cost

An integrated design means less moving parts and easier module replacement. This saves you cost and hassle. The sensor array, image processing, light source, and lens are all integrated into this line scanner.

Large Line Scan Width for your Large, Flat Surface AOI Equipment

The IPL line scan camera module design seamlessly combines to increase its scanning width up to 3 meters. This makes it a good fit for large, flat surface machine vision applications.

Utilizing the IPL to Attain the Comprehensive Scan

The IPL line scan camera supports many inspection methods. Two common methods will be shown below. The convey line setup is the first scanning method where the panel under inspection passes through the stationary IPL camera on a conveyor belt line.

The second method, called the flatbed, is the opposite, where the IPL camera moves from one end of the stationary panel to another.

The IPL, like many other machine vision cameras, uses a single line of sensor pixels to capture the inspected object's image one line at a time. After an external signal (called the frame trigger pulse or FTP) is activated, the line scan camera begins scanning lines of pixels.

The IPL's pixel sensors receive the inspected object's reflected lighting from the IPL's in-built RGB illumination as the object moves along a conveyor belt (or as the IPL line scan camera moves over the object). The pixel data from the IPL is then transmitted by camera link to the frame grabber that is installed in a PC where the image data is ready for software analysis.